Categories

- Conical Spring Mechanical Seals

- Parallel Spring mechanical Seals

- Multiple Spring mechanical Seals

- Wave Spring Mechanical Seal

- Metal Bellows mechanical seal

- Cartridge mechanical seal

- PTFE-Bellows Seal

- Parallel Spring Diaphragm Mechanical Seal

- Elastomeric Bellows mechanical seal

- Brand Pump Seals-General Industrial

- Brand Pump Seals-Food and Beverage Industry

- Stationary seat Type

TG1

John Crane Type1 Replacement

Elastomer Bellows mechanical seal TG1 is suitable for a wide range of service condition. TG1U,TG1K conform with US and UK standard respectively. Type 1 mechanical seal range is designed for universal application: pumps, mixers, air compressors, fans and other rotating equipment. It is frequently used in the pulp and paper, petrochemical, food processing, wastewater treatment, chemical processing and power generation industries.

Elastomer Bellows mechanical seal TG1 is suitable for a wide range of service condition. TG1U,TG1K conform with US and UK standard respectively. Type 1 mechanical seal range is designed for universal application: pumps, mixers, air compressors, fans and other rotating equipment. It is frequently used in the pulp and paper, petrochemical, food processing, wastewater treatment, chemical processing and power generation industries.

Detail Information

Features

Reliable transmission due to special design in the drive band and drive notches.

Special balancing in the elastomer bellows. design,avaliable in high-pressure application

Single seal、balanced、Bi-directional

Good interchange ability, TG1U Dimensional data conform with US standard, TG1K conform with UK standard.

Available in metric and inch sizes

Recommended Applications

Water and waste water technology

Petroleum chemical industry

Industrial pumps。

Process pumps。

Other Rotating Equipment

Operating range

Shaft diameter: d1=16...75mm(0.625'' ...3.000'')

Pressure: p=0...1.7Mpa(246.5psi)

Temperature: t = -40 °C ...200 °C(-40°F to 392°F)

Sliding velocity: Vg≤13m/s(42.6ft/m)

Notes: The range of preesure,temperature and sliding velocity is depend on seals combination materials

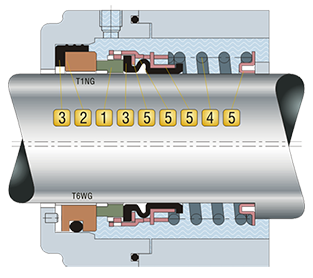

Product Structure

Combination Materials

1. Rotary Face

Carbon graphite resin impregnated Ak

Tungsten carbide W1

Silicon carbide (RBSIC) O

2. Stationary Seat

Aluminium oxide(Ceramic) B

Silicon carbide (RBSIC) O

Tungsten carbide W1

3. Auxiliary Seal

Nitrile-Butadiene-Rubber (NBR) P

Fluorocarbon-Rubber (Viton) V

Ethylene-Propylene-Diene (EPDM) E

4. Spring

Stainless Steel (SUS304) F

5. Metal Parts

Stainless Steel (SUS304) F

Stationary Seat

Standard Stationary Seat: T1NG,T1N

T1NG equivalent to John Crane NG

T1N equivalent to John Crane N

Alternatives Stationary Seat: T6WG,T6W

T6WG equivalent to John Crane WG

T6W equivalent to John Crane W

Review

- Loading...

Please send your message to us

If you have any questions please ask here. TNG® needs the contact information you provide to us to contact you about our products and services. For information on our privacy practices and commitment to protecting your privacy.

- Tel

- *Title

- *Content

Do you need any further information?

Please send your message to us

If you have any questions please ask here. TNG® needs the contact information you provide to us to contact you about our products and services. For information on our privacy practices and commitment to protecting your privacy.

- Tel

- *Title

- *Content