Categories

- Conical Spring Mechanical Seals

- Parallel Spring mechanical Seals

- Multiple Spring mechanical Seals

- Wave Spring Mechanical Seal

- Metal Bellows mechanical seal

- Cartridge mechanical seal

- PTFE-Bellows Seal

- Parallel Spring Diaphragm Mechanical Seal

- Elastomeric Bellows mechanical seal

- Brand Pump Seals-General Industrial

- Brand Pump Seals-Food and Beverage Industry

- Stationary seat Type

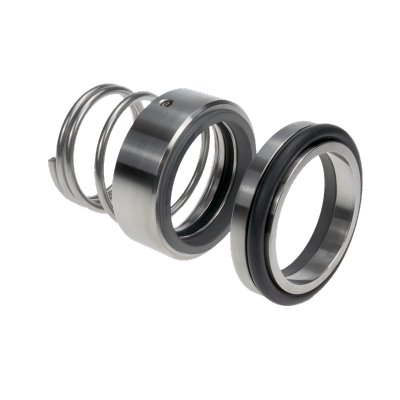

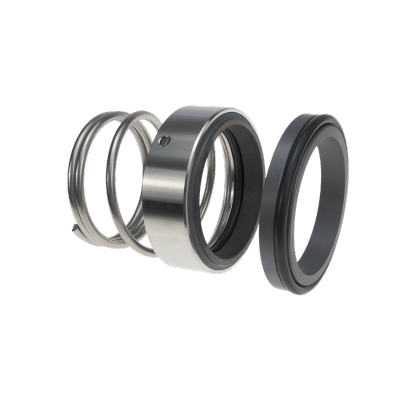

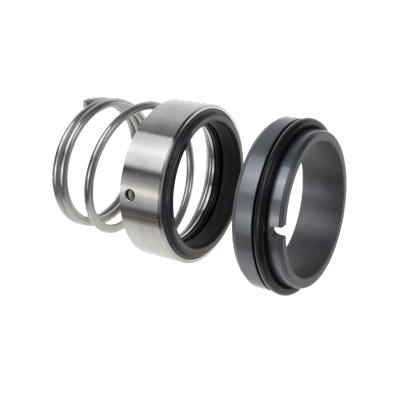

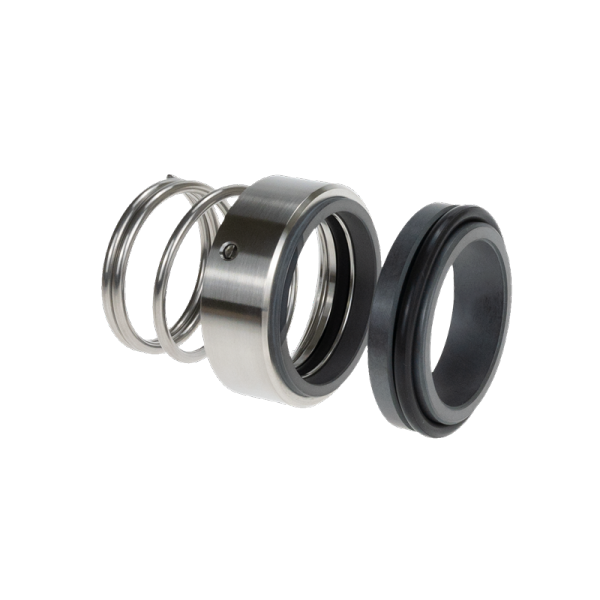

TG120DG

ROTEN Type2 Replacement

Conical spring and O-ring pusher construction mechanical seals type TG120DG is designed for large batch production. With reliable performance, wide range of applications and easy installation features. Used in the different media conditions due to extend material options. It is ideal for use in paper industry,sugar industry, chemical and petroleum, food processing, sewage treatment industry .

Conical spring and O-ring pusher construction mechanical seals type TG120DG is designed for large batch production. With reliable performance, wide range of applications and easy installation features. Used in the different media conditions due to extend material options. It is ideal for use in paper industry,sugar industry, chemical and petroleum, food processing, sewage treatment industry .

Detail Information

Features

Seal face inlaid SlC SSlC TC

Unbalanced Seal

Rotating conical spring

Dependent on direction of rotation

TO EN 12756.1S0 3069

Recommended Applications

Paper and sugar industry,Food Processing,waste water technology

Low solids content or viscous media

Sewage pumps, chemical pumps, screw pumps, process pumps

Other Rotating Equipment.

Operating range

Shaft diameter: d1=10...100 mm

Pressure: p=0...1.5Mpa(217.5psi)

Temperature: t = -20 °C ..+120°C(-4°F to 248°F)

Sliding velocity: Vg≤15m/s(49.2ft/s)

Notes: The range of preesure,temperature and sliding velocity is depend on seals combination materials

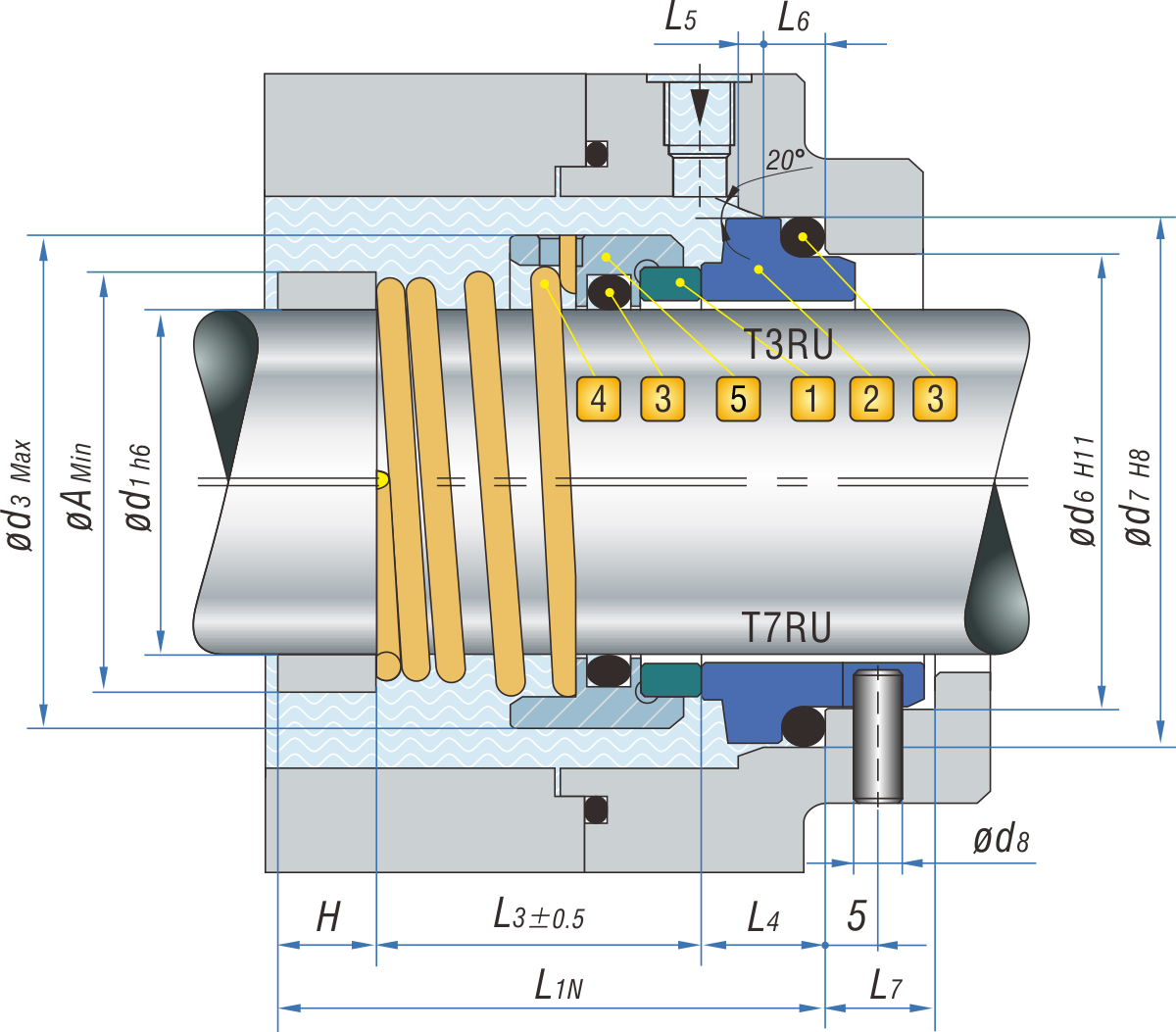

Product Structure

Combination Materials

1. Rotary Face

Reaction Bonded Sic RBSIC O

Sintered Silicon Carbide SSlC O1

Tungsten Carbide.Ni-binder W

2. Stationary Seat

Reaction Bonded Sic RBSIC O

Sintered Silicon Carbide SSlC O1

Tungsten Carbide.Ni-binder W

3. Auxiliary Seal

Encapsulated 0-ring Elastomers 0-ring

FEP Jacketed FKM M1 FKM V

FEP Jacketed VMQ M3 EPDM E

PFA Jacketed FKM M5 VMQ S

4. Spring

GrNi-Steel (AlS1304) F

GrNiMo-Steel (AlS1316) G

5. Metal Parts

GrNi-Steel (AlS1304) F

GrNiMo-Steel (AlS1316) G

Review

- Loading...

Please send your message to us

If you have any questions please ask here. TNG® needs the contact information you provide to us to contact you about our products and services. For information on our privacy practices and commitment to protecting your privacy.

- Tel

- *Title

- *Content

Do you need any further information?

Please send your message to us

If you have any questions please ask here. TNG® needs the contact information you provide to us to contact you about our products and services. For information on our privacy practices and commitment to protecting your privacy.

- Tel

- *Title

- *Content