Categories

- Conical Spring Mechanical Seals

- Parallel Spring mechanical Seals

- Multiple Spring mechanical Seals

- Wave Spring Mechanical Seal

- Metal Bellows mechanical seal

- Cartridge mechanical seal

- PTFE-Bellows Seal

- Parallel Spring Diaphragm Mechanical Seal

- Elastomeric Bellows mechanical seal

- Brand Pump Seals-General Industrial

- Brand Pump Seals-Food and Beverage Industry

- Stationary seat Type

TG670

John Crane Type 670 series replacement

The Type TG670 series seal is a welded metal bellows rotating seal with 45'c bellow design, which makes the stress distribution more reasonable and flexibility, to ensure seals has advantages of reliable sealing and good matching property. The seal has excellent dynamic performance and has a wide range of applications.

The Type TG670 series seal is a welded metal bellows rotating seal with 45'c bellow design, which makes the stress distribution more reasonable and flexibility, to ensure seals has advantages of reliable sealing and good matching property. The seal has excellent dynamic performance and has a wide range of applications.

Detail Information

Features

Welded metal bellows

Bi-dire ctional

Balanced

0-ring auxiliary seal

Comply with APl682 requirements

Available with DOUBLE-PLY Bellows

TG670G、TG670Tseals, equivalent to Type 676

TG670Cseal, equivalent to Type 670

Recommended Applications

Refining technology, Oil and gas industry

Process industry

Pumps

Special Rotating Equipment.

Operating range

Shaft diameter: d1=18...100mm(0.750"...4.000")

Pressure: p=0...2.5Mpa(362.5psi)

Temperature: t = -40 °C ...290 °C(-40°F to 554°F)-TG670C

t = -20 °C ...220 °C(-4°F to 428°F)-TG670T

t = -20 °C ...150 °C(-4°F to 302°F)-TG670G

Sliding velocity: Vg≤25m/s(or Vg≤5,000rpm)(82ft/s))

Notes: The range of preesure,temperature and sliding velocity is depend on seals combination materials

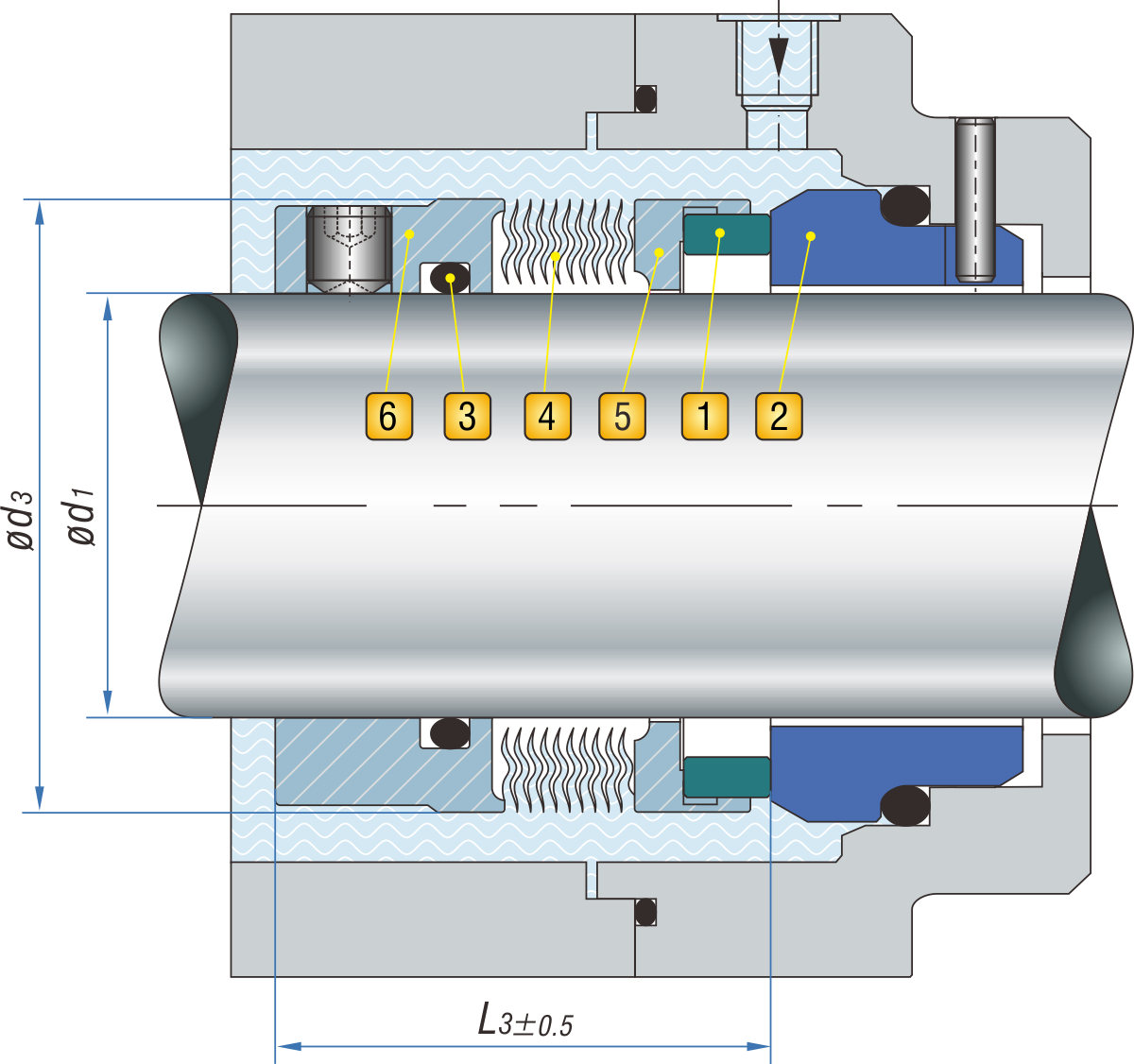

Product Structure

Combination Materials

1.BELLOWS

CriiMo-steel G AM350 M8 Hastelloy C-276 M5

2.SEAL FACE

Carbon graphite AD Sintered Silicon O1 Sintered Silicon O1

antimony impreg Carbide SSlC Carbide SSIC

3.AUXILIARY SEAL

FKM V FKM V FKM V

EPDM E FFKM K PEP M1

NBR P FFKM K4.ROTARY HEAD

CrNiMo-steel G All0y 42 T4 Hastelloy C-276 M5

5.METAL PATRTS

CrNiMo-steel G CrNiMo-steel G Hastelloy C-276 M5

6.APPLICATION

Non-corrosive medium Mildly corrosive medium Corrosive medium

Review

- Loading...

Please send your message to us

If you have any questions please ask here. TNG® needs the contact information you provide to us to contact you about our products and services. For information on our privacy practices and commitment to protecting your privacy.

- Tel

- *Title

- *Content

Do you need any further information?

Please send your message to us

If you have any questions please ask here. TNG® needs the contact information you provide to us to contact you about our products and services. For information on our privacy practices and commitment to protecting your privacy.

- Tel

- *Title

- *Content